How pallet wrapping machine repair helps in enhancing packaging efficiency

Discover the Vital Benefits of Utilizing a Pallet Wrapping Machine in Your Storehouse Operations

In modern storage facility operations, the fostering of pallet Wrapping machines is ending up being progressively essential. These devices streamline the packaging procedure, enhancing effectiveness while substantially lowering labor expenses. They additionally guarantee regular Wrapping high quality, which is necessary for item defense during transit. Nonetheless, the benefits extend past just these aspects. There are added advantages that can change storage facility administration, making it worthwhile to explore better.

Improved Efficiency in Packaging Workflow

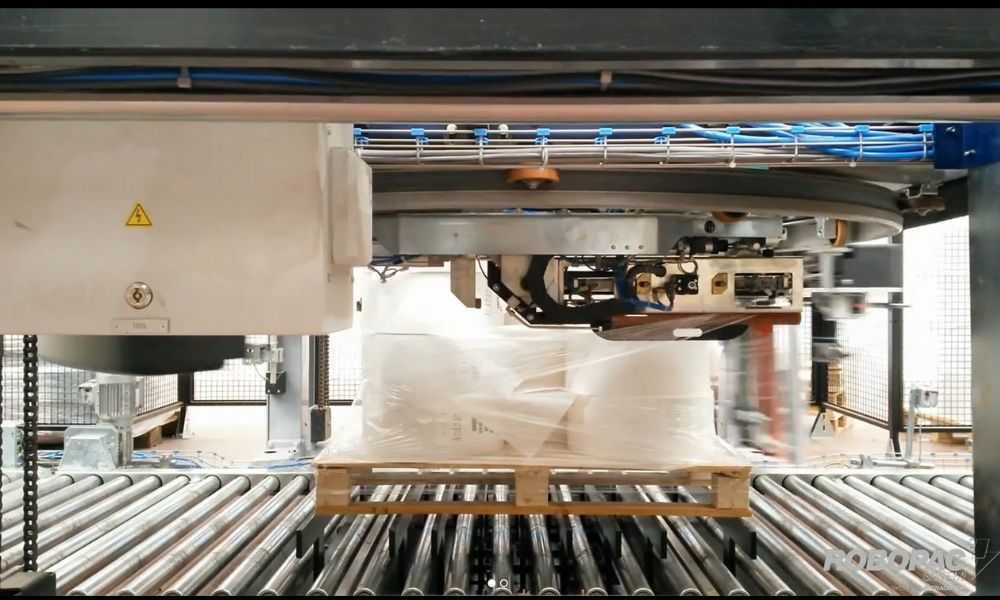

In the domain name of logistics, performance stands as an extremely important purpose, and pallet Wrapping equipments significantly add to attaining this objective. These devices simplify the packaging process by automating the Wrapping of items, guaranteeing that products are firmly packaged with very little hand-operated treatment. By reducing the time invested on Wrapping, businesses can enhance their operations, permitting quicker turnaround times and improved throughput. In addition, pallet Wrapping devices provide constant Tension and coverage, boosting the protection of products during transport. This dependability minimizes the threat of product damages, which can cause costly delays. In general, the assimilation of pallet Wrapping machines into product packaging operations cultivates an extra reliable, trustworthy, and arranged approach to logistics management.

Substantial Labor Price Cost Savings

While firms seek to decrease functional expenditures, the fostering of pallet Wrapping machines can cause substantial labor expense savings. By automating the Wrapping process, these equipments reduce the requirement for manual work, allowing staff members to concentrate on even more critical jobs. With the capacity to cover pallets quickly and consistently, fewer employees are needed to complete packaging operations, resulting in lower payroll costs. In addition, the machines enhance efficiency as they can operate constantly, reducing downtime related to hands-on Wrapping. pallet wrapping machine repair. This efficiency equates to much faster turn-around times and enhanced overall operations. Training workers to operate these equipments typically needs much less time compared to training for manual Wrapping strategies, further contributing to lowered labor costs in stockroom procedures.

Boosted Product Defense During Transportation

Regular and Dependable Wrapping Quality

Pallet Wrapping machines provide constant and dependable Wrapping quality, making certain that every pallet is wrapped evenly regardless of driver experience. This uniformity decreases the danger of damages during transportation, as appropriately covered pallets keep their stability. The equipments apply an optimal quantity of stretch film, reducing waste and ensuring that the tons is protected efficiently. Unlike manual Wrapping, which can differ considerably based on the employee's strategy, a computerized procedure guarantees that each pallet obtains the very same degree of defense. This reliability not just improves the safety and security of products yet likewise simplifies operations, permitting an extra efficient process. Eventually, the constant Wrapping top quality provided by these makers leads to improved customer contentment and decreased expenses connected with product loss.

Raised Storehouse Room Application

Reliable storehouse area her explanation use is an important consider maximizing procedures, and pallet Wrapping equipments play a substantial duty in attaining this objective. By safely Wrapping pallets, these makers decrease the danger of product damages throughout storage and transport, enabling a lot more effective piling and storage methods. Boosted security means that pallets can be packed greater without jeopardizing safety and security, which maximizes vertical room usage. In addition, the constant Wrapping procedure guarantees uniform dimensions, enabling far better organization and efficient use of readily available space. This brings about lowered aisle width requirements and enables even more item to be stored in the exact same area. Overall, employing a pallet Wrapping device improves area efficiency, adding to streamlined storage facility operations and enhanced efficiency.

Frequently Asked Inquiries

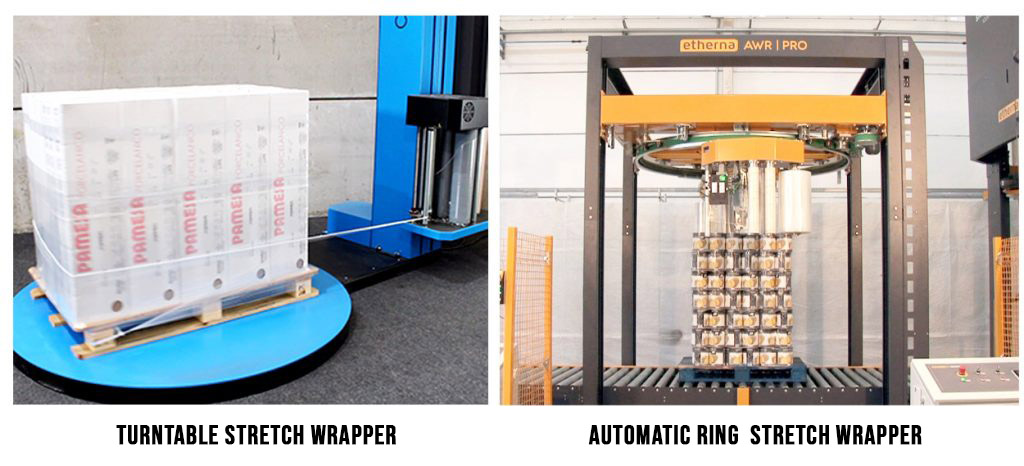

What Kinds of Products Can Be Wrapped Making Use Of a Pallet Wrapping Maker?

Numerous items can be wrapped using a pallet Wrapping equipment, consisting of boxes, pallets of food, commercial goods, and delicate things. The equipment fits diverse sizes and shapes, guaranteeing secure packaging for efficient transport and storage.

Just how much Does a Pallet Wrapping Device Typically Price?

The price of a pallet Wrapping equipment typically varies from $3,000 to $20,000, depending upon capacities and functions. Factors such as automation degree and brand credibility can substantially affect the final rate.

Can Pallet Wrapping Machines Be Integrated With Existing Warehouse Solutions?

Pallet Wrapping machines can often be incorporated with existing storage facility systems, enhancing performance (pallet wrapping machine repair). This integration permits structured procedures, enhanced inventory administration, and better coordination with various other automated procedures, eventually enhancing overall storehouse functionality

What Is the Maintenance Demand for Pallet Wrapping Machines?

The maintenance requirements for pallet Wrapping makers look at this now typically include routine examinations, lubrication of moving components, and replacement of worn elements. Sticking to these practices guarantees peak performance and long life, reducing operational interruptions in storage facility settings.

Exist Safety And Security Worries When Using Pallet Wrapping Machines?

When making use of see page pallet Wrapping devices include potential injuries from moving components, inappropriate handling, and inadequate training, safety concerns - pallet wrapping machine repair. Making certain appropriate safeguards, regular maintenance, and employee education can significantly lower these threats in warehouse environments